In terms of sustainability measures, monomaterial structures are already making good headway and will evolve even further.

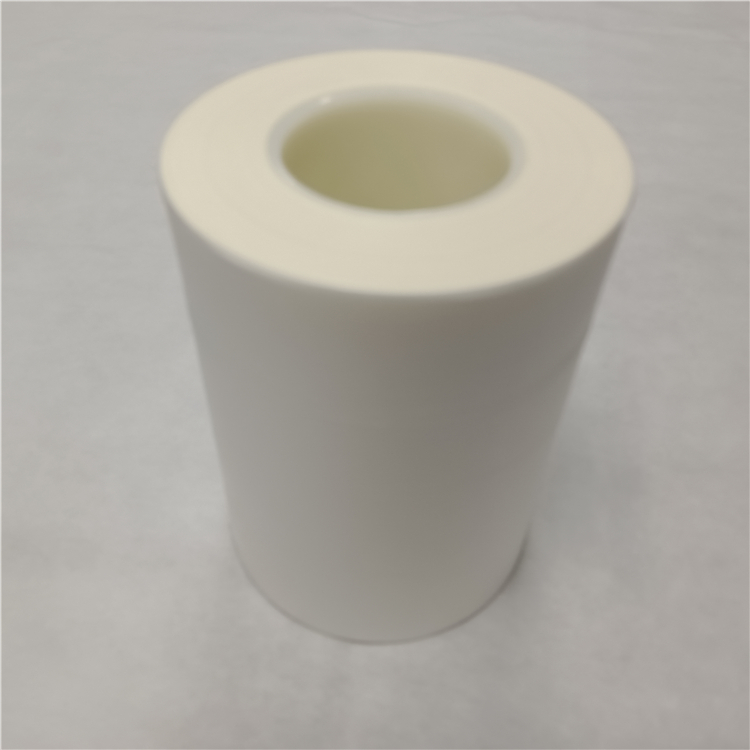

In last month’s blog In Sustainable Packaging, the Word is ‘Monomaterial’, posted by my colleague, executive editor Matt Naitove, he addressed how a growing trend in packaging, and even outside of it, grew out of developments in materials and processing technology that all monomaterial structures—typically all-PE or all-PE—is aimed at replacing laminations, coextrusions and “composites” utilizing paper, aluminum, barrier resins or highly dissimilar polymers (like PET with polyolefins). He noted that that this trend is certainly ranking highly in industry sustainability efforts as recyclability of such structures eliminates that need for mechanical separation,, making the goals of recovery and reuse .much more attainable. Pe Film Roll Material

Matt also noted that this trend has not been new in automotive where we have seen a migration to all-polyolefin solutions (based mainly on PP) in place of vinyls, urethanes and styrenics to facilitate recycling. He also referred to a newer development on which hs has reported whereby automotive and nonautomotive fuel tanks are now being being blow molded in a special enhanced-barrier nylon 6, Akulon Fuel Lock from DSM Engineering Plastics, which enables monolayer fuel tanks in place of multilayer HDPE alternatives

Now, going back to the packaging arena, I expect we are not only going to see continued growth in this trend but with even more ‘sustainability’ built in to monolayer structures, something that is likely underway. By that I’m referring to the use of mechanically recycled polyolefins and/or chemically recycled grades that can replace at least some of the layers of multilayer all-polyolefin packaging.

Let’s take a look at some history and development along the way. One could argue that the seeds of the monomaterial trend came about in the early 2000s when ExxonMobil and Dow launched their metallocene catalysts PE elastomers. Within the next two decades, we saw others join with either metallocene or other advanced single-site catalyst materials—both based on PE and PP, and they included Nova Chemicals and, later, SABIC. While, it may not be necessary to use these higher-performance materials in all types of monolayer structures, depending on the application, they have had a big impact, particularly in the food packaging arena.

At the same time, polyolefin suppliers have also been tweaking their processes to produce advanced grades of PE and PP, which they do not attribute to ‘novel’ catalyst systems per se. They include the four players above as well as others like LyondellBasell, Braskem, Ineos Polyolefins, and Borealis. And, as noted above, While the fast-growing monomaterial movement in both food and non-food packaging is also evolving to include mechanically recycle content (PIR and PCR) as well as chemically recycled materials. Nearly all the major polyolefin players have developed such resin portfolios.

In February 2019, we reported on the key applications that have been driving growth of PE.

We noted that specialty, higher-performance grades have been developed to meet major market trends, which include sustainability, consumer convenience, and evolving E-commerce packaging needs. Input from supplier ExxonMobile, Nova Chemicals and Braskem was sought. Three of the half dozen applications noted were:

• Moving from multi-material to monomaterial, recyclable flexible films: In many food-packaging applications, including stand-up pouches and flow wrappers, films are commonly made using mixed materials in the structure. Numerous brand owners are working with suppliers and converters to redesign those structures to eliminate foil, nylon or other materials in order to meet both consumer demand for sustainability and the aggressive recyclability timelines that the plastics industry has set through the American Chemistry Council. Where multilayer blown and cast films, along with lamination, have been the dominant production technologies for many applications, oriented PE in films like machine-direction or biaxially oriented PE are being explored now to deliver stiffer and tougher all-PE films.

• Conversion of two-piece (PP + PE liner) to one-piece (all-PE) closures: The movement from two-piece to one-piece closures in carbonated soft-drink and hot-fill applications has begun in earnest in North America, as the mono-material composition makes closures easier to recycle. That means just one part must provide all the required properties, and the interaction between the closure design, the resin and the way it’s molded are all critical to producing closures that will perform consistently.

• Expanding the uses of post-consumer recycled (PCR) content: Across the industry there is much R&D on technology for creating “clean” recycled PE streams and finding ways to incorporate them into finished products with performance comparable to virgin resin.

Here are some other articles on which we have reported on the monomaterial develoopments worth noting :

Back in a 2016 article, we reported on a Vietnamese manufacturer of laminated flexible packaging.

Thanh Phu Plastic Packaging Co. Ltd. sought to address the market’s demand for a more readily recyclable alternative to conventional laminated structures, which this company also makes. Such structures typically include BOPA, BOPET, and BOPP laminated with either PE or PP. In collaboration with ExxonMobil experts, Thanh Phu produced a package that can be recycled in the same collection stream as PE by using ExxonMobil’s new Exceed XP and Enable mLLDPE polymers and its own Veloflex film- converting technology. “This is a true synergy between material science and conversion technology innovation,” says Alex Dam, executive v.p. at Thanh Phu. “We have changed the cradle-to-grave cycle into a more responsible cradle-to-cradle concept. Our aim is to have a full PE alternative to conventional laminated solutions without compromising performance, while maintaining an attractive cost-efficiency ratio.”

The company has produced commercial packages and pouches for feminine-hygiene and adult-incontinence products and baby diapers for both Japan’s Unicharm Corp. and Kimberly-Clark, New Milford, Conn. The company has also developed an all-PE package for frozen uncooked seafood and other such non-barrier frozen applications to replace the current nylon /PE laminate. Also jointly developed with ExxonMobil— Thanh Phu produced a 100% PE/PE laminated stand-up pouch, using Veloflex technology for Unicharm Vietnam.

In July/2020, we reported on the growing trend of BOPE within the last two previous years.

As with all-PE blown film, the drivers for this monomaterial option are sustainability and the circular economy. Nova Chemicals appears to have led this followed by SABIC which launched its first LLDPE for BOPE films at K2019, showing examples of BOPE standup pouches suitable for confectionary and snacks; frozen, fresh and dried fruit and vegetables; and packaging for personal-care products. BOPE boasts good printability, high mechanical properties and toughness, as well as very high seal integrity. SABIC’s new material also enables BOPE film to provide controlled, linear tear direction, thus making the package easy to open.

Meanwhile, Nova had been collaborating with several organizations across the supply chain to develop monomaterial BOPE packaging, focusing on a particularly pressing market need for bi-oriented HDPE (HD-BOPE) for the tenter-frame process to replace multimaterial packaging based on bi-oriented polypropylene (BOPP) or PET (BOPET).

Nova says HD-BOPE packaging is more easily recyclable and can enable higher recycling rates for flexible packaging and help brand owners achieve their circular-economy commitments. While BOPP has a decades-long head start in bi-oriented films, HD-BOPE has potential to become an industry standard for recyclable packaging over the next several years, according to Owen Lightbody, technical service’s team leader for performance films.

While the profile of BOPE has been elevated by the combination of sustainability commitments made by brand owners and the attractiveness of monomaterial packaging for enhanced recyclability, the reality is that the supply chain is mainly equipped with legacy tenter-frame lines designed around PP. The primary challenge is developing HDPE technology that has a suitable orientation window to be processed on these existing tenter frames.

Nova collaborated with leading tenter-frame machine builder Bruekner Group to optimize HDPE resin technologies for BOPE and accelerate the commercialization of HD-BOPE films. Areas of focus were extrusion output and achieving reliable production with no film breaks. Continued improvement in output rates will be achieved through a combination of novel PE resin architecture and equipment optimization such as Brueckner’s novel BOPP/BOPE hybrid tenter-frame design.

Highly specialized resins that offer a tailored viscosity profile for the tenter-frame process, extremely low gels, and lot-to-lot consistency are required for processing defect-free films, according to Nova experts.

In October 2021, we reported on caps and closures made of HDPE and how Nova Chemicals expects this to the future.

Expect HDPE with post-consumer recycle (PCR) and post-industrial recycle (PIR) content to become dominant in future caps and closures for foods and beverages as well as for non-food packaging. This is the view of Brant Wunderlich, Nova’s market manager for caps & closures.

While he concedes that today’s PP caps and closures outnumber HDPE by a two-to-one margin, he sees this trend already changing as HDPE gains traction. “Polyethylene has a much higher recycling rate than PP, so we are aiming to design for recycle as well as material reduction. Polypropylene caps typically have an LDPE liner, so HDPE enables an all-PE closure, making it a better partner to PET beverage bottles that are currently much more highly recycled than PP/LDPE caps.”

Also likely to play a significant role in closures of the future are “tethered” closures to ensure the cap stays on the bottle and enters the recycle stream with it so it does not become litter. These are already required by EU regulation that takes effect in 2024. Wunderlich concludes that PCR incorporation and tethering are likely to shift industry priorities.

In an August, 2022 blog, we reported on how blown-film extrusion supplier Hosokawa Alpine was contributing to the circular economy, as part of a series of industry interviews prior to K 2022 developed by VDMA, Germany’s mechanical engineering industry association.

Hosokawa sales manager Joachim Oberbauer, described how blown PE film can make packaging more recyclable and the increasing demand for products made with recycled materials. “We are the pioneer of MDO (machine-direction orientation) technology in the blown film world. It is based on mono-axial film stretching and enables the improvement of properties of the end product. By further developing MDO technology, we have succeeded in taking a significant step towards the production of sustainable packaging from blown film. This further development has made so-called full-PE solutions or monomaterial solutions a possibility, so that this technology makes a significant contribution to the recyclability of plastic.” With the help of our MDO technology, the blown film world can produce packaging that can replace materials such as PET, for example.

A normal stand-up pouch, of which you see thousands throughout supermarkets everywhere, is typically made of different plastics, such as PET laminated against an inner layer of PE blown film for instance. Composites of that nature are not recyclable. You can shred those PET and polyethylene composites, but you can no longer use them in similar applications. By using MDO technology, for example, the PET can be replaced by polyethylene. The blown film is stretched again, which allows it to be altered mechanically and optically.

This bestows the PE film with improved properties that were previously covered by the PET film, for example. This allows a product to be made solely from polyethylene. Such a monomaterial product can be recycled and used again to produce film.

In March 2022, we reported on a series of hexene LLDPE film resins from ExxonMobil with never seen before levels of performance. Produced with a proprietary metallocene catalyst, Exceed XP 7021 and 7052 are said to deliver remarkable mechanical performance with a combination of low density and fractional melt index that enable the production of innovative new film structures not previously possible. This potential covers a range of applications, including moisture-barrier construction, stretch-hood, collation shrink and greenhouse films

The company has been working closely with processors to develop new film formulations that many in the industry say are ahead of their time, according to Tom Miller, Exceed XP 7 PE product manager.

Among these collaborators is Tex-Trude, a 70-yr-old privately held company based in Channelview, Tex., where it runs three main divisions—for PE blown film, PVC profile extrusion and flexible vinyl compounding—out of one manufacturing plant.

Charlie Nettles III, Tex-Trude’s president, says the company is using Exceed XP 7 in new formulations for vapor-barrier construction films designed for use under concrete slabs, as well as stretch-hood packaging films. Based on the excellent results achieved with these products, Nettles anticipates that within a few months, Tex-Trude will use XP 7 in other film-packaging applications, such as lawn & garden, mulch and other chemicals. Tex-Trude extrudes vapor-barrier films in thicknesses from 10 to 20 mils. Nettles noted that the material provides a huge improvement in dart-drop impact consistency—90+% compared with 50-60% achieved from previously used resins.

In May 2022, we reported on yet another new series of hexene-based LLDPE film resins from ExxonMobil, said to have “industry-leading combinations of stiffness and toughness” while being easy to process.

Produced with a proprietary metallocene catalyst, Exceed S performance LLDPEs provide opportunities to reduce the complexity of film formulations and structures while improving processing, converting, film performance and package durability.

Targeted for use in food, industrial and agricultural applications, Exceed S resins can enhance monomaterial design for recycle and help enable recycle-containing solutions while unlocking film and package production efficiencies, according to Tom Miller, marketing manager.

The Exceed S series currently comprises three grades. Due to their outstanding stiffness and toughness, along with better melt strength and higher output than current mLLDPE resins, Exceed S resins allow film designers and engineers to rethink film design for simpler solutions. Miller reports that LDPE and HDPE can either be eliminated or amounts reduced, depending on the needs of the application.

In June 2022, we reported on PP made with renewable feedstock from Borealis Among the first successful commercial examples of the use of Bornewables PP from is the new Aino packaging ice cream tubs and lids launched by Finland’s ice cream manufacturer Froneri.

The new application is the result of Borealis’ partnership with Froneri and Germany-based global plastics packaging manufacturer Paccor. The feedstock for the Bornewables PP from Borealis is derived from second-generation bio-mass, waste and residue streams that are not competing with the human food chain.

The new tubs and lids are injection molded from fully-functional monomaterial Bornewables PP by Paccor in an integrated process with in-mold labelling decoration, which also makes this innovative monomaterial packaging 100% recyclable. The feedstock for the Bornewables PP is derived from second-generation biomass, waste and residue streams that are not competing with the human food chain. Moreover, the renewable material is used as a highly efficient drop-in solution without any further modifications required to the partners’ manufacturing and packaging lines. At the same time, it helps them reduce their carbon footprint.

Read: Custom Downstream Systems Appoints New Territory Sales Manager

In December 2022, we reported on an excellent example of Braskem’s collaborative industry efforts that debuted at K 2022--the result of the company’s partnership with SLM Extrusion to develop high-performance stretch films with recycle content. It included the use of Braskem’s Wenew post-consumer recycled (PCR) portfolio of PE resins and SML’s new technology. For several years, the two companies have collaborated on different aspects in the development of high-quality stretch film. More recently, they were able to produce market-conform stretch films containing at least the PCR content (30%) demanded by brand owners and stipulated in legal regulations.

Like others, the company has an entire sustainability program in place—in their case, branded Wenew. Its core focus is to develop and promote high-quality circular products, such as polymers and chemicals produced from mechanical recycling, advanced recycling or as a result of Braskem’s traditional production process. The goal is always to ensure maximum quality when used in Braskem's new products and can thus act as role models for broader use throughout the industry.

Many conditions must be met to get the best wall distribution in a PET bottle. Skilled operators are, as always, indispensable.

Synthetic paper based on filled polyethylene or polypropylene film has been around for decades without causing much excitement--until recently.

Though often criticized, MFR is a very good gauge of the relative average molecular weight of the polymer. Since molecular weight (MW) is the driving force behind performance in polymers, it turns out to be a very useful number.

Film Biodegradable Compostable © 2023 Gardner Business Media, Inc. Privacy Policy [Log On]